Festo

Ikke kategoriseret

CRDSNU-20-10-P-A

Festo CRDSNU-20-10-P-A Brugsanvisning

Her er Festo CRDSNU-20-10-P-A (Ikke kategoriseret) brugervejledning. 2 sider på sprog med en vægt på 400,539.0 Mb. Hvis du ikke kan finde svar på dit problem Spørg vores community.

Side 1/2

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1 Applicable documents

All available documents for the product www.festo.com/sp.è

2 Safety

2.1 Safety Instructions

– Take into consideration the ambient conditions at the location of use.

– Only use the product in original status without unauthorised modifications.

– Observe labelling on the product.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– Prior to mounting, installation and maintenance work: Switch off compressed

air supply and secure it from being switched back on.

– Observe tightening torques. Unless otherwise specified, the tolerance is

±20%.

2.2 Intended use

The product is intended for the transport of loads.

2.3 Training of skilled personnel

Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

3 Further information

– Accessories www.festo.com/catalogue.è

– Spare parts www.festo.com/spareparts.è

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

5 Product overview

5.1 Function

The piston rod moves outwards when the cylinder chamber is pressurised. The

advanced piston rod is retracted as follows:

– For double-acting cylinders, by pressurising the other cylinder chamber.

The cylinder force during advance and return is:

– different with piston rod at one end.

– identical with through piston rod.

The position of the piston can be detected by proximity switches.

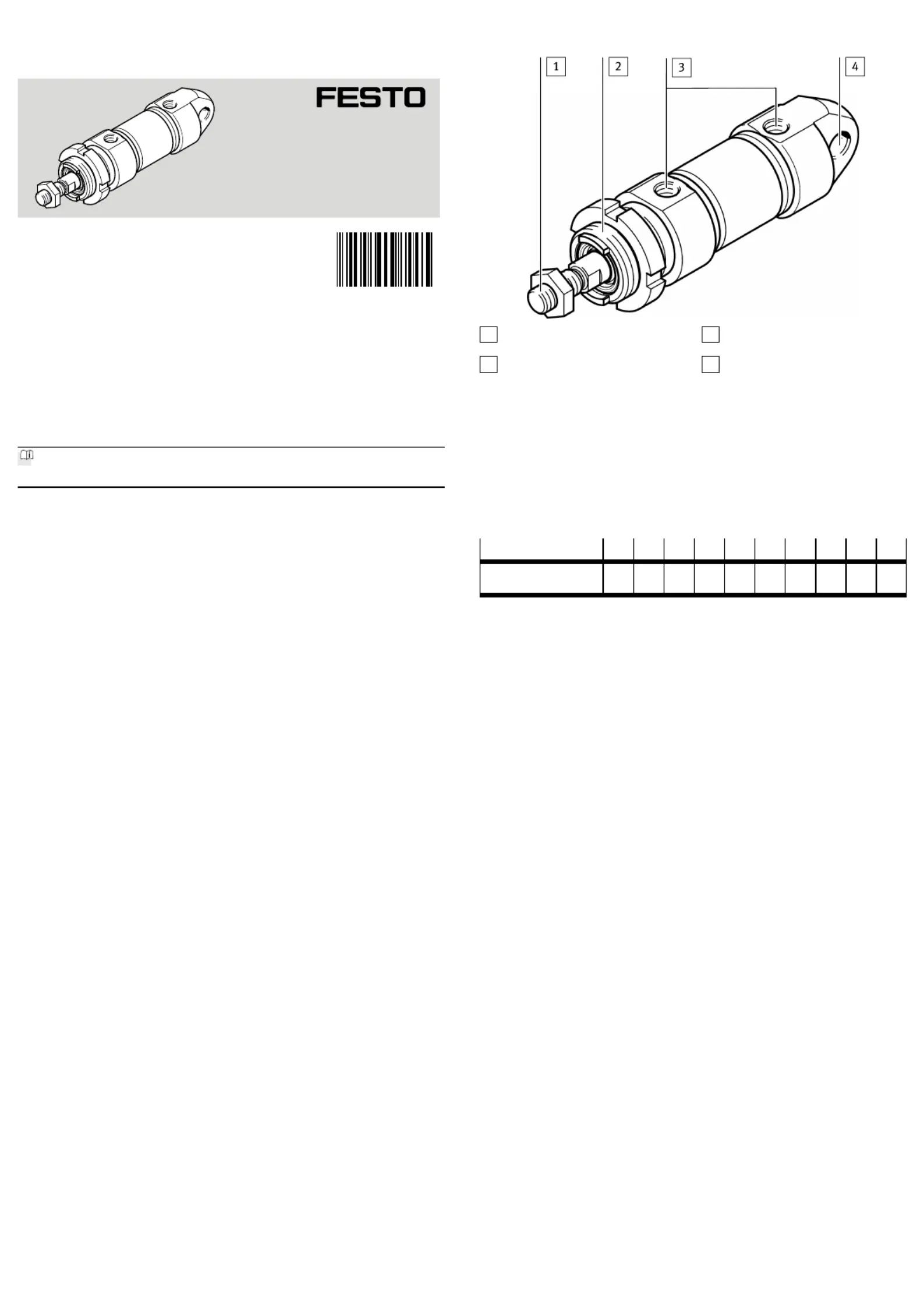

5.2 Design

1

Male thread on the piston rod for

mounting the payload

2

Male thread on the bearing cap for

mounting

3

Supply ports in the bearing/end

cap

4

Cross hole for mounting

Fig. 1 Sample illustration CRDSNU

5.3 Mounting

• Handle the cylinder so as to avoid any damage to the cylinder barrel and pis-

ton rod.

• Observe the following points:

– parallel mounting when using external guides

– installation without distortion

– Compliance with the permissible loads www.festo.com/catalogueè

• Observe tightening torque of lock nuts on the male thread .2

Size 12 16 20 25 32 40 50 63 80 100

Tightening torque

on the bearing cap

[Nm] 15 15 40 40 60 80 100 100 550 550

Tab. 1 Tightening torques on the bearing cap

• Avoid mechanical alignment inaccuracies between the piston rod and an

external guide using one of the following measures:

– absolutely precise alignment (general)

– use of a self-aligning rod coupler FK

– use of a guide unit FEN with compensating coupling

A rigid coupling impairs the service life and function of the cylinder.

5.4 Mounting Accessories

In the case of a large payload, high piston speed or when using quick exhaust

valves:

• Use suitable shock absorbers or external stops.

To prevent the payload from sliding down suddenly in the event of an air supply

failure in a horizontal or sloping mounting position:

• Use piloted check valves.

To set the speed:

• Use one-way flow control valves in the following supply ports:

– For single-acting cylinders: GRLZ (supply air)

– For double-acting cylinders: GRLA (exhaust air)

The one-way flow control valves are screwed directly into the supply ports. Use of

other accessories with a screw-in depth that is too long will damage the cushion-

ing piston.

For position sensing with proximity sensors:

• Use proximity sensors with mounting kit.

Avoid external influence caused by magnetic or ferritic parts in the vicinity of

the proximity sensors (spacing 10mm).³

6 Installation

6.1 Pneumatic Installation

• Connect tubing to supply ports.

7 Commissioning

7.1 Preparation

• Pressurise the system slowly. A soft start valve is used for gradual start-up

pressurisation www.festo.com/catalogue. è

With medium or large payloads or at high speeds:

• Use sufficiently large arrester fixtures. The product will tolerate the maximum

velocities and payloads without external arrester fixtures

èwww.festo.com/catalogue

8143197

CRDSNU

Round cylinder

8143197

2021-01c

[8143199]

Operating instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Problemløsning Festo CRDSNU-20-10-P-A

Hvis du har læst manualen omhyggeligt, men ikke fundet en løsning på dit problem, bed andre brugere om hjælp

Specifikationer

| Mærke: | Festo |

| Kategori: | Ikke kategoriseret |

| Model: | CRDSNU-20-10-P-A |